The tapes for bonding paper or film, assembly collars for engravings, and engravings-assembly tape are just a few examples from our full range for manufacturing and processing of paper.

Making each work look as good as possible

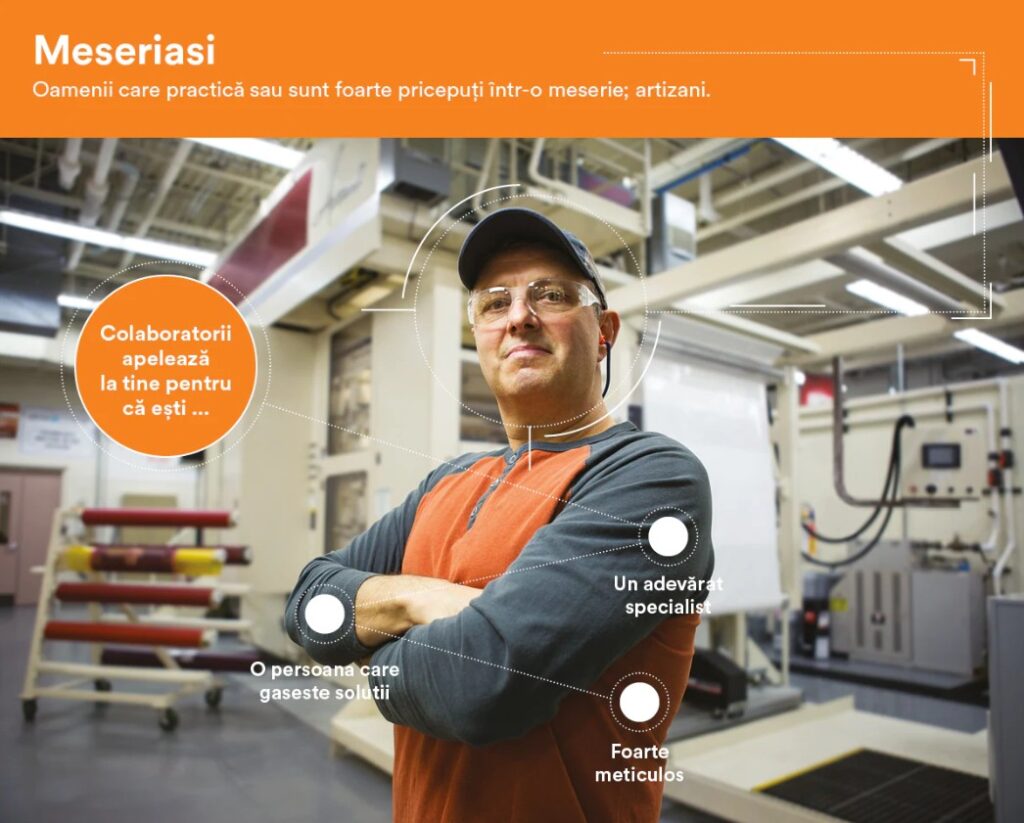

You care about your job: you are passionate about understanding everything correctly and to dedicate yourself to make certain that each printwork, delivered by your printer, is a work of art. What makes you stand out from the crowd is the fact that your expertise lies not only in the qualification you hold, but also in your day-to-day experience.

Your expertise and your experience both tell you that, for any flexographic printing, you need tape to anchor the engravings, and printing solutions capable of providing an optimal, constant and productive quality.

Every time. From every angle.

Respect your profession using the 3M printing quality advantage.

You have dedicated your career to the art of flexographic printing. You are in search of more than just a supplier, you are looking for a partner that may provide solutions and be there for you in your attempt to achieve a perspective. The 3M flexography experts dedicated their work to finding means to aid you in honouring your commitment to your profession, throughout all stages of the printing process.

Plate anchoring must be perfect: it requires focus and plate anchoring skills and configuration skills, for accurately configuring cylinders. We help you to correctly carry out this action.

During the printing run, observe the quality of printing, while at the same time, feeling the way the printer operates. We help you maintain a smooth operation, without any issues, at every printing run.

Whenever the printing operation has concluded, disassembly becomes the moment of truth. We shall guide you in reducing the incident of plate damage and operator fatigue.

Advantages

Optimal

You need a flexographic tape appropriate for every work, irrespective of whether it is small density, to maximise the reproduction of points, high density, for a solid colour field, or somewhere in-between the two. We provide the largest range of tape densities in the industry, so that you may select the specific one, best matching the needs of the current work.

Find out how we can help you find the optimal combination of features for every work, from selecting the right density in the plate anchoring chamber, to selecting the right adhesive that may help you in the post-printing removal.

Consistent

We provide one of the tightest tolerances in the industry, so that your flexographic tape has the same thickness - be it at the beginning, or at the end of the reel - or even at a different reel.

Find out more about how we can help achieve consistency of technologies helping in the removal of air bubbles upon setting adhesives, which reduces the damages to the plate upon disassembly.

Productive

Air bubbles and edge raising are the enemy, thereby interrupting the printing process and reducing yield to extreme levels. Our flexographic anchoring tapes can help, by providing air removal and strong adherence, so that your printer continuously operates.

The way in which we contribute to improving yield with the features of adhesives and of foam, which shall help you throughout your process, from the first correct anchoring to the disassembly with reduced force, in order to reduce damages to the plate and the operator’s fatigue.