The issue / challenge submitted to us for settlement, by the client:

A solution for the supply of a double-sided tape part for assembly of a side fascia, at the exterior of the car body.

The customer’s suggestion was to carry out the assembly using 3 adhesive tape parts on each plastic component.

The solutions proposed by us:

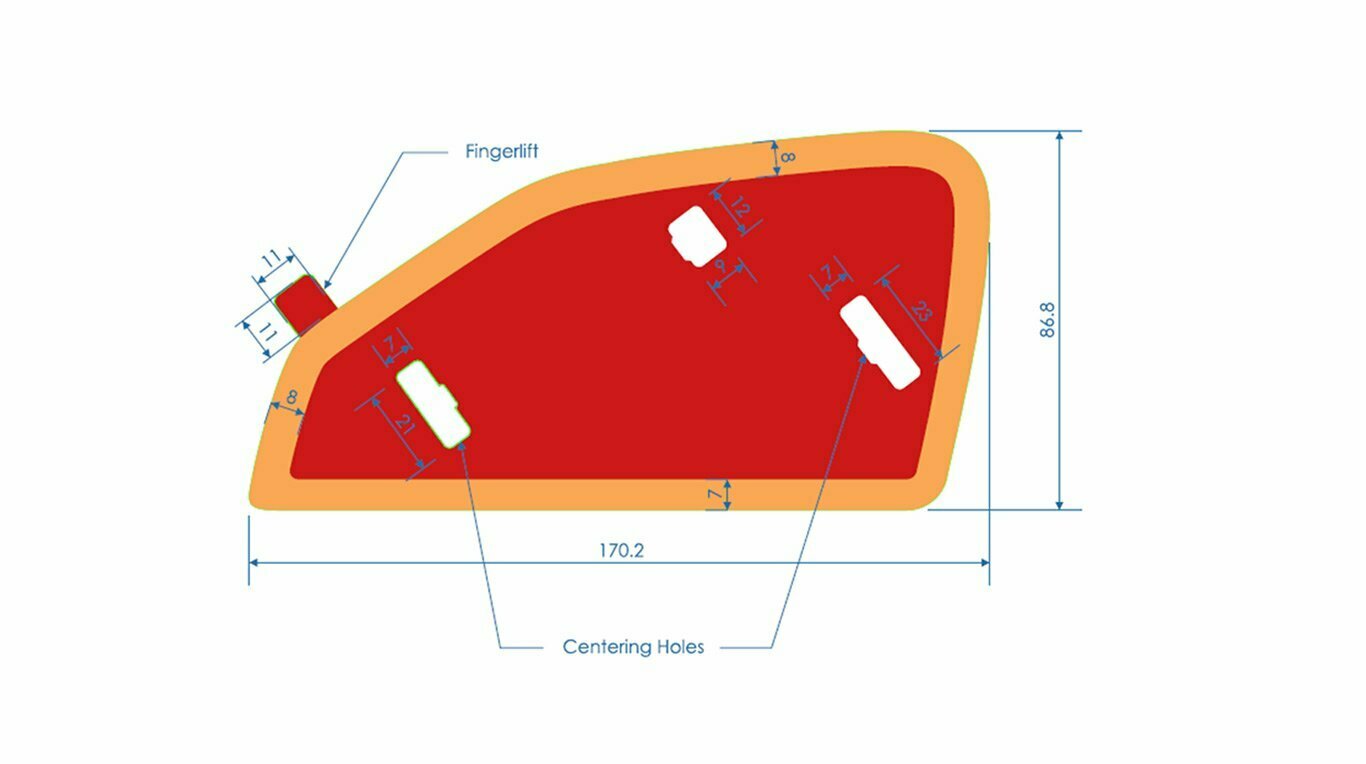

MDE Converting proposed the replacement of the 3 double-sided tapes with full frame individually-cut parts.

The innovation of MDE Converting: The support liner is providing with guiding holes, for application ease and accuracy.

Efficiency for the customer (time-saving, money-saving, high efficiency, dealing with a technical issue)

The full frame definition settled the issue of alignment of the 3 adhesive tape parts, as initially proposed by the customer.

Based on the proposed solution, the customer has improved their cycle times for the process of applying the double-sided tape inlay.

The full frame format provides an even appearance, compared to the initial definition, which minimizes the risk of potential quality issues of our customer, such issues originating from the OEM, in relation to the appearance of the blending of the body and fascia.

Scrap rate minimised.

Forecasted parts volume:

– 100k sets (LH & RH)

Common challenges in car fascia assembly

In modern automotive manufacturing, assembling these particular parts with adhesive tape, requires precision, repeatability, and consistency. Manual application using multiple tape sections or inconsistent bonding, can lead to quality rejections or visible defects on the vehicle.

Other pain points may include:

- Lack of process repeatability in high-volume production

- Time loss due to misalignment

- Tolerance stack-up from multiple tape sections

One important aspect, is that irregular contours and complex shapes only increase these challenges. When multiple tape parts are involved, the risk of inconsistent placement grows along with material waste and rework time. Plus, the gaps between adhesive lines become common, especially under time pressure or when handled by different operators.

All of these issues, can become more complex at high volumes. Manufacturers need repeatable car fascia tape placement with minimal room for error. This is a critical requirement as assembly cycles accelerate. Because many automotive applications require precise integration, standard tape rolls or off-the-shelf solutions can rarely be effective choices.

The importance of custom-made parts

The use of full-frame, die-cut adhesive formats can simplify the assembly operations and ensure consistency on each car fascia unit. Moreover, no two parts are identical in geometry, surface treatment, or mounting method. That’s why custom adhesive layouts, are crucial.

MDE Converting, specializes in engineering tape solutions that precisely match the needs of each part and production setup. Our custom die-cut tapes, provide better adhesion to different substrates and higher process stability than generic alternatives.

Here are other advantages of customized adhesive parts for fascia car:

- Less rework and human error

- Fewer application steps

- Improved bonding strength

- Enhanced durability and performance

By tailoring the components to the geometry and function of the application, we help manufacturers maintain high quality standards and optimize cycle times. These specific adhesive parts, aren’t just an upgrade but a necessity in modern automotive workflows.

Adhesive solutions for various car fascia components

These car components can vary across vehicle models, ranging from side trims and covers to sensor housing and lower bumper extensions. They often have complex shapes, irregular surfaces, or specific mounting zones which makes generic tapes inadequate.

MDE Converting can support all types of fascia car parts, such as front and rear bumper covers or wheel arch moldings. Furthermore, we can design door and window trim pieces, side skirts, and rocker panel inserts. Depending on the application, we adapt our processes to meet precise performance and design criteria.

For OEMs and Tier-1 suppliers who seek efficiency, quality, and reliability in adhesive bonding processes, we are a partner they can trust in the long run. We support the automotive industry, as well as any other dinamic sector looking to enhance operational efficiency and develop better products.