The issue / challenge submitted to us for settlement, by the client:

A solution for the supply of a double-sided tape part and services for the assembly thereof on the plastic part.

Very tight tolerance on alignment of the adhesive tape part on the plastic part.

The solutions proposed by us:

MDE Converting cut the adhesive tape part.

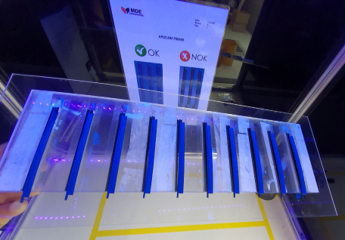

MDE Converting innovation: the development and implementation of a complete line for assembly of the adhesive tape on the plastic part, by observing the steps and requisites provided by the strict procedures for the bonding of 3M acrylic adhesive tape. (surface cleaning with dimethyl carbinol, primer application on the premises equipped with UV light, application of appropriate pressure)

In-house development of jigs appropriate for cleaning, primer application and 3D printing adhesive tape alignment.

Development, in cooperation with a pneumatic industrial equipment producer, of a semi-automated mill.

Efficiency for the customer (time-saving, money-saving, high efficiency, dealing with a technical issue)

The process fully developed by MDE Converting led to the successful assembly of the double-sided tape part on the plastic part.

Unlocking our client’s project, plastic part injector, level 2 supplier, who did not manage to assemble adhesive tape according to the extremely tight alignment tolerances.

Forecasted parts volume:

200.000 pcs./year