AUTOMATION SYSTEM FOR ADHESIVE TAPES

Reduce manufacturing times, improve ergonomics and avoid material waste

Obstacles in applying tape, worker injuries, material waste... These are issues that may find an easy solution with an applicator or dispenser for automation of adhesive tape processes.

Automatic adhesive tape dispensers

Models:

START ZCM SERIA 1000 ORIGINAL

- The START ZCM1000 Original line measures, distributes and cuts out all types of adhesive tape (tissue, film, PE foam, acrylic foam...)

- Recommended capacity: up to 2,500 cuts per day

- Strips from 3 to 50 mm in width. (Un/version).

- Tape length: 5 to 999 mm

- Digital calibration (LED display). Automatically measures, cuts and distributes

- Sizes: 24.5 x 13.7 x 15 cm

- CE Certificate: Yes

START TDA-080 SERIA ORIGINAL

- START TDA-080 heavy dispensers. They are the benchmark for reliability, accuracy, speed and low maintenance.

- Recommended capacity: up to 2,500 cuts per day

- Strips from 6 to 80 mm in width. (Un/version).

- Tape length: 15 to 9999 mm

- Digital calibration (LED display). Automatically measures, cuts and distributes

- Sizes: 22.9 x 16.8 x 30.5 cm

- CE Certificate: Yes

START SERIA TDA-150 ORIGINAL

- START TDA-150 provides higher speed, power and cutting widths, of up to 150 mm in width, or more adhesive tapes at the same time.

- Recommended capacity: up to 2,500 cuts per day

- Strips from 6 to 150 mm in width. (Un/version).

- Tape length: 15 to 9999 mm

- Digital calibration (LED display). Automatically measures, cuts and distributes

- Sizes: 10" x 13" x 13"

- CE Certificate: Yes

START TDA-025 Carusel ORIGINAL

- The START TDA-025 tape dispenser, also known as the ‘Carrousel’, is ideal for very narrow or very thin tapes.

- Recommended capacity: up to 2,500 cuts per day

- Strips from 3 to 25 mm in width. (Un/version).

- Tape length: 15 to 20 mm

- Wheel adjustment and carrousel triggered by button

- Dimensiuni: 30 x 16 x 16 cm

- CE Certificate: Yes

Automatic dispensers for labels and cut parts

Models:

Labelmoto LD 3000 SERIES

- The LABELOTO LD3000 label dispenser is indicated for reduced work areas.

- Label width is 6 to 57 mm

- Label length: 6 to 76 mm

- Feed rate: 56 mm per second

- Maxim reel diameter: 190 mm (508 mm with optional TD STAND accessory)

- Optional: Sensor for clear labels; PLC; version for EPA areas.

- CE Certificate: Yes

Labelmoto LD 6000 SERIES

- The Labelmoto LD 6000 series provides high work speed and a higher label compatibility.

- Label width is 6 to 121 mm

- Label length: 3 to 152 mm

- Feed rate: 168 mm per second

- Maxim reel diameter: 305 mm (508 mm with optional TD STAND accessory)

- Optional: Sensor for clear labels; PLC; stand; version for EPA areas.

- CE Certificate: Yes

Labelmoto LD 8000 SERIES

- Reference in several industries, such as, quick loading and the available size of labels.

- Label width is 6 to 127 mm

- Label length: 3 to 305 mm

- Feed rate: 84 mm per second

- Maxim reel diameter: 305 mm (508 mm with optional TD STAND accessory)

- Optional: Sensor for clear labels; PLC; stand; version for EPA areas.

- CE Certificate: Yes

The Labelmoto LDX SERIES

- Increased yield with very large labels combining speed, control and reliability.

- Label width is 6 to 203 mm

- Label length: 3 to 305 mm

- Feed rate: 168 mm per second

- Maxim reel diameter: 305 mm (508 mm with optional TD STAND accessory)

- Optional: Sensor for clear labels; PLC; stand; version for EPA areas.

- CE Certificate: Yes

Automatic non-adhesive tape cutters

Models:

START ZCM1500

- The START ZCM1500 model is indicated particularly for adhesive tapes with protection (aluminium tape, VELCRO tapes, reflective tape for trucks etc.)

- Up to 50 mm in width

- Tape length: 20 to 999 mm

- Feed rate: — mm per second

- Digital calibration (LED display). Automatically measures, cuts and distributes

- Sizes: 24.5 x 13.7 x 15 cm

- CE Certificate: Yes

START TBC 50 / TBC 50S

- START TBC50 industrial cutter Automatically measures, cuts and distributes non-adhesive tapes, such as, nylon, nomex, thermal-contracting tubes, 3M Dual Lock, VELCRO tapes etc.

- Up to 110 mm in width

- Tape length: 10 mm to 300 m

- Cutting speed (50 mm): 120 -140 pieces per minute

- Digital calibration (LED display). Automatically measures, cuts and distributes

- Sizes: 85 x 32 x 38cm (18kg)

- CE Certificate: Yes

START TBC 50H HOT CUT

- The START TBC50H model is the variant with hot-cutting head, to cut tapes, belts, sleeves, tapes, rope etc., avoiding loose wires and creating an even cutting line.

- Up to 90 mm in width

- Tape length: 15 mm to 100 m

- Cutting speed (50 mm): 120 -140 pieces per minute

- Digital calibration (LED display). Automatically measures, cuts and distributes

- Sizes: 82 x 37 x 38 cm (20.5 kg)

- CE Certificate: Yes

START TBC 552L / TBC 553L

- Fully-automated heavy-duty industrial cutter (measures, cuts out and distributes) non-adhesive tape: nylon, sleeves, Nomex, Velcro, thermal-contracting tube etc. high speed.

- Up to 210/ 310 mm in width

- Tape length: 10 mm to 300 m

- Feed rate: 32 metres per minute

- Digital calibration (LED display). Automatically measures, cuts and distributes

- Sizes: 51 x 69 x 94cm (85kg)

- CE Certificate: Yes

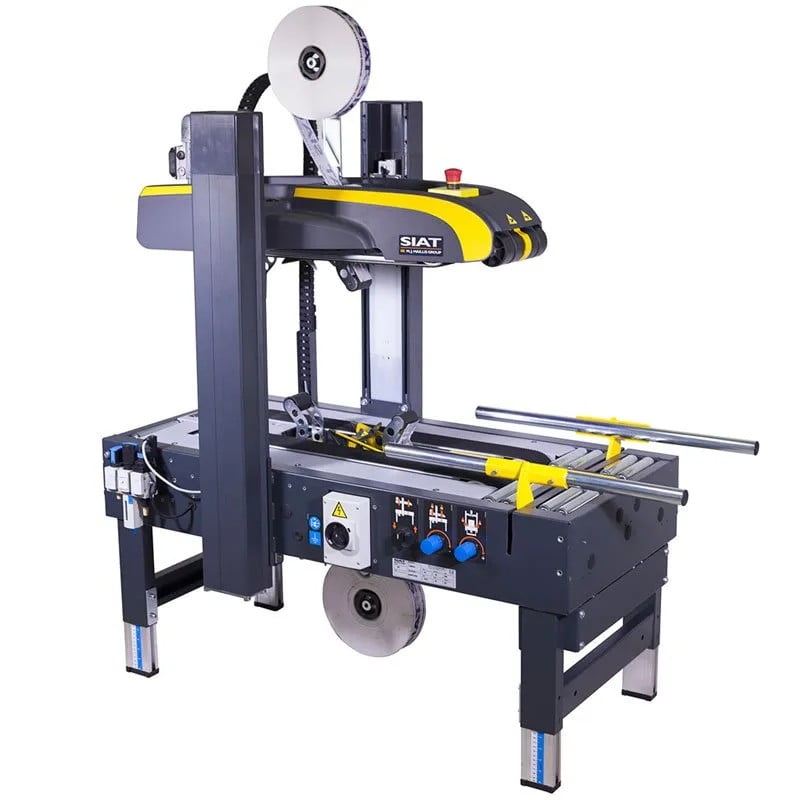

Box sealant

Increase productivity using an automated cover sealing device

Models:

SIAT SK 20

- Fixed format Lower/upper high strength drive belts

- Min./max. length of cover: 150 / ∞ mm

- Min./max. width of box: 140 / 500 mm

- Min./max. height of box: 100 / 500 mm (90 mm opt.)

- Min./max. weight of box: 0.5 / 32 kg

- Driving tapes: double lower + upper motor

- Tape applicators: 2x: Down + Up Both detachable 50mm / 75mm opt.

- CE Certificate: Yes

SIAT S8

- Fixed format High-strength side belts

- Min./max. length of cover: 150 / ∞ mm

- Min./max. width of box: 120 / 500 mm

- Min./max. height of box: 100 / 500 mm

- Min./max. weight of box: 0.5 / 32 kg

- Driving tapes: double side motor

- Tape applicators: 2x: Down + Up Both detachable 50mm / 75mm opt.

- CE Certificate: Yes

SIAT XL 36

- Fixed format High-strength side belts

- Min./max. length of cover: 150 / ∞ mm

- Latime min./max. a cutiei: 150 / 650 mm

- Min./max. height of box: 100 / 650 mm

- Min./max. weight of box: 0.5 / 32 kg

- Driving tapes: double side motor

- Tape applicators: 2x: Down + Up Both detachable 75mm / 50mm opt.

- CE Certificate: Yes

SIAT SR 20

- Multi -format High-strength lower/upper driving belts

- Min./max. length of cover: 150 / ∞ mm

- Min./max. width of box: 140 / 500 mm

- Min./max. height of box: 100 / 500 mm

- Min./max. weight of box: 0.5 / 32 kg

- Driving tapes: double lower + upper motor

- Tape applicators: 2x: Down + Up Both detachable 50mm / 75mm opt.

- CE Certificate: Yes

Functional capabilities of electronic dispensers

Electronic tape dispensers are designed to automate the cutting of adhesive materials. These systems, ensure consistent tape length and accuracy across multiple cycles. They’re ideal for production processes that are standardized or repetitive.

Depending on the model, these dispensers can process a wide range of materials. For example, they’re effective for processing foam tape, Kapton, VHB, double-sided or linerless tape. Many units, allow users to preset the exact cutting lengths, enable continuous feed, and adjust dispensing speed to suit the material characteristics.

Here are some extended technical features:

- Compatibility with narrow, wide, or irregular tape formats

- Automatic feed or manual dispensing with adjustable increments

- Anti-jam and auto-reverse mechanisms for safer use

- Quick roll changes without recalibration or extended downtime

Electronic dispensers, can be easily operated in multiple ways, such as push-button, photo sensor or foot pedal. They allow flexible control that suits many production layouts. Plus, their electric-only architecture, makes them simple to install and maintain. Their compact size, fits easily into manual workstations or semi-automated environments.

Industry applications and operational use cases

These tape dispensers, are used in operations that require repeatable tape application and strict placement specifications. They eliminate the manual steps that consume time and ensure accuracy, especially in short-cycle or multi-product workflows.

Because they’re really effective, many industries integrate them into various operations. In e-commerce and logistics, they speed up the packaging lines by dispensing tear tape or resealable strips. In automotive, they assist in placing vibration insulation, bonding elements, or foam gaskets. Furthermore, in electronics, they provide controlled application of insulating tapes.

Practical use cases may include:

- Kit assembly lines, with defined tape cuts for each item

- Manual workbenches requiring uniform tape segments

- Applications where tapes must be applied in narrow areas

- Small-batch production with high-quality requirements

At MDE Converting, we recommend these automated dispensers to all manufacturers looking to optimize their processes, without adding complexity to their workflows. The adaptability of these systems, makes them well suited for both established production environments and growing operations.

The benefits of using electronic dispensers

Using an electronic tape dispenser, improves the operational consistency and reduces the errors associated with manual taping. These devices, ensure that every piece of tape is cut to the correct length, with minimal operator input and no need for constant readjustments.

Because they’re automated, companies can avoid time and material waste, rework and variability. This results in higher-quality output and leaner operations. Plus, most of the systems, can be installed without major reconfiguration and require minimal training.

Another advantage of these dispensers, is that they don’t use a lot of energy and are easy to relocate across different workbenches. Their durability and ease of use, make them a long-term investment that improves the production flow and optimizes costs.